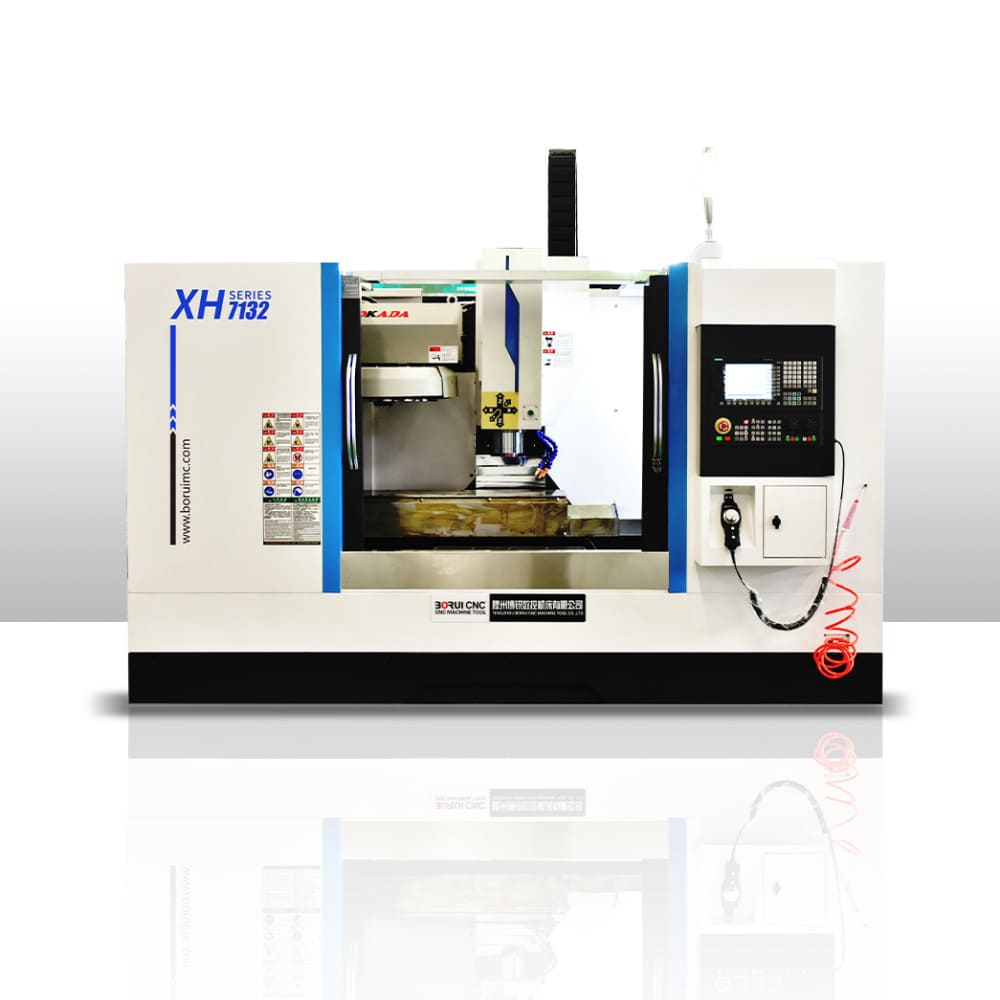

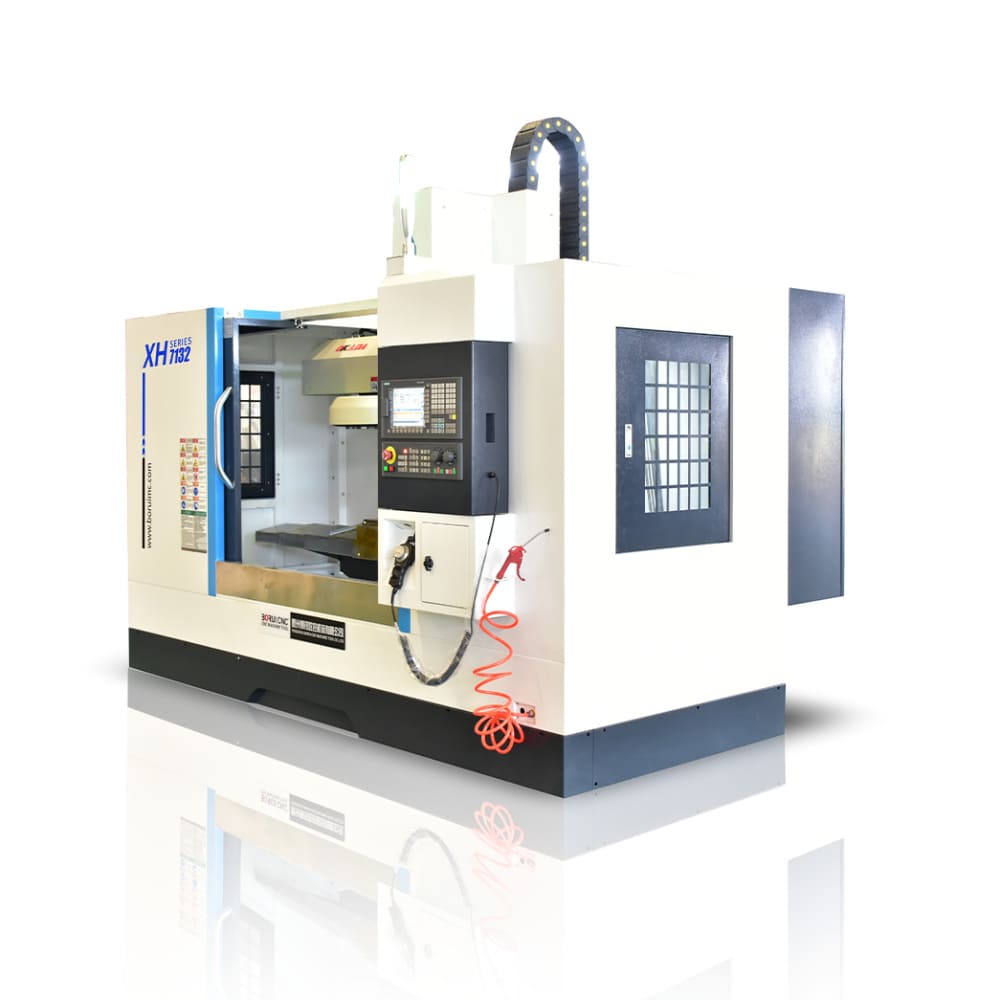

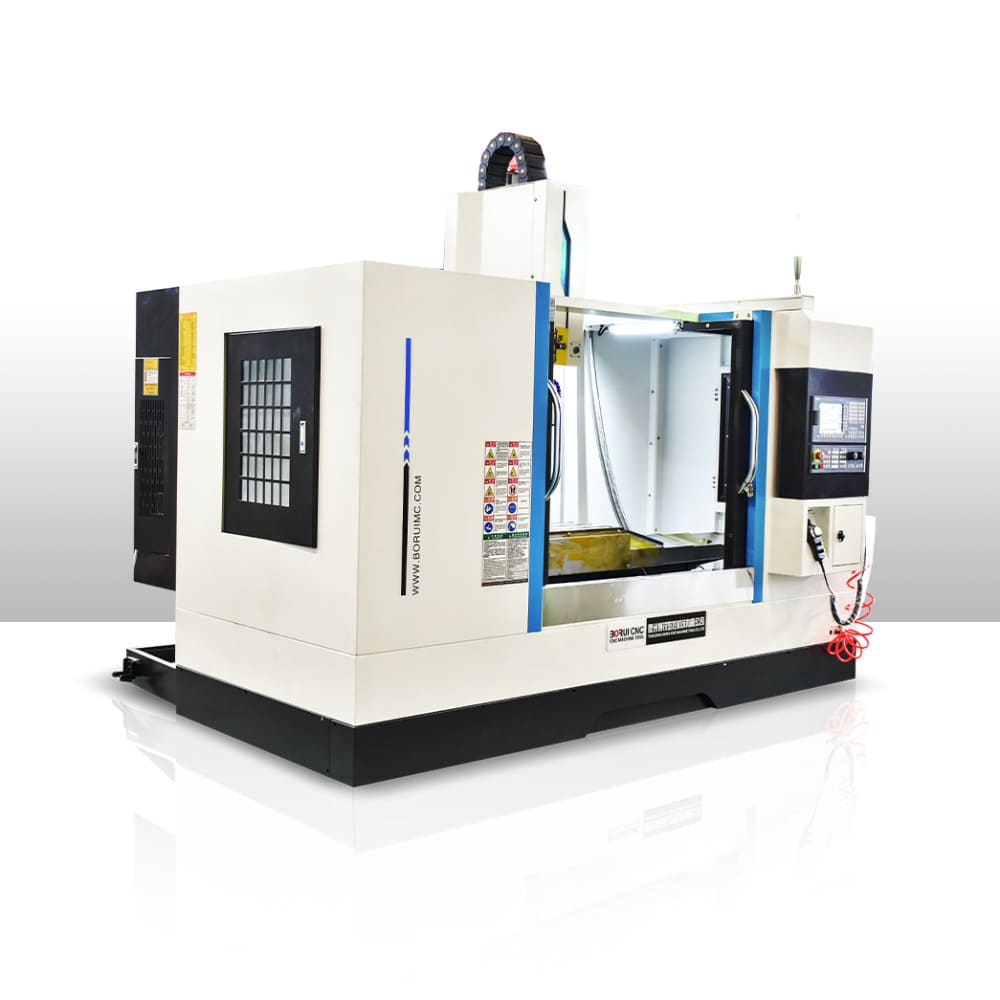

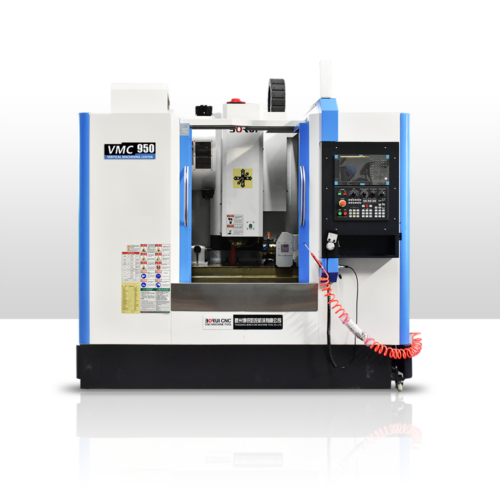

CNC Vertical Machine Center Features

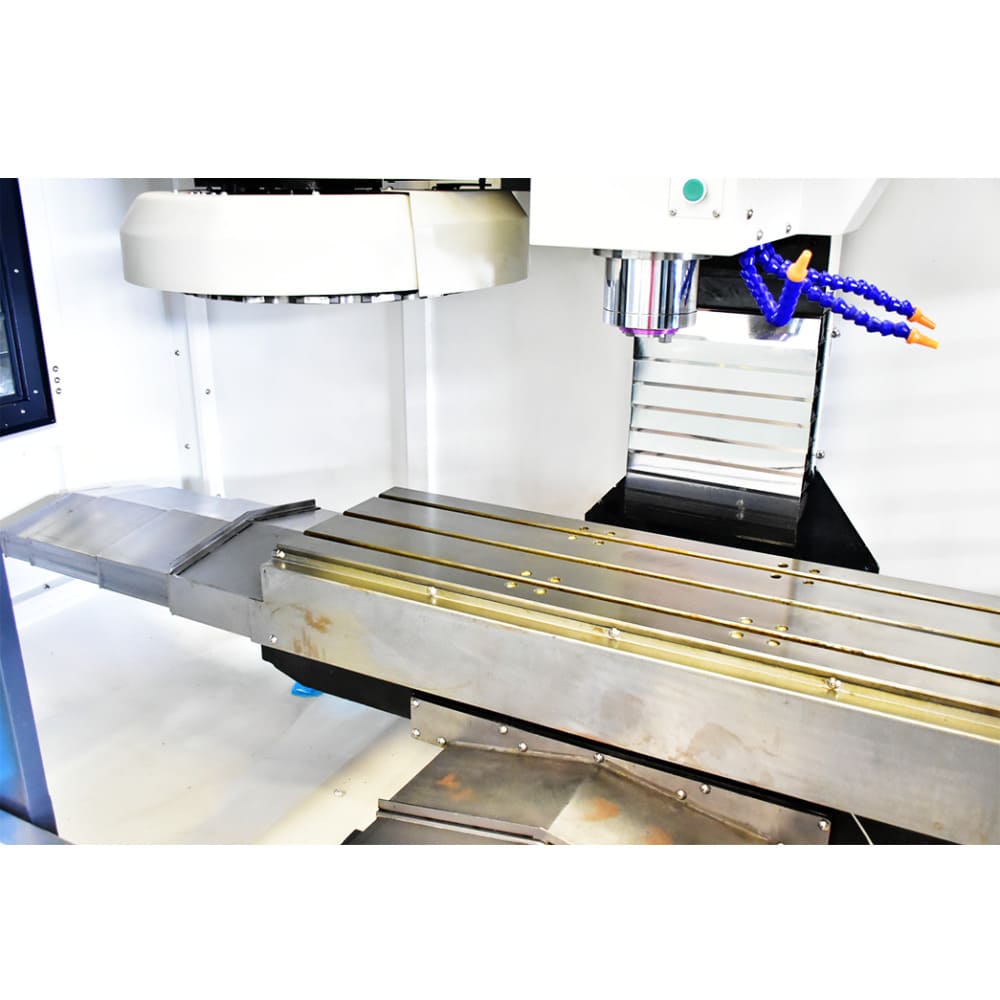

- High-precision hard guideway and screw.

- A high-quality casting body ensures the machine’s rigidity

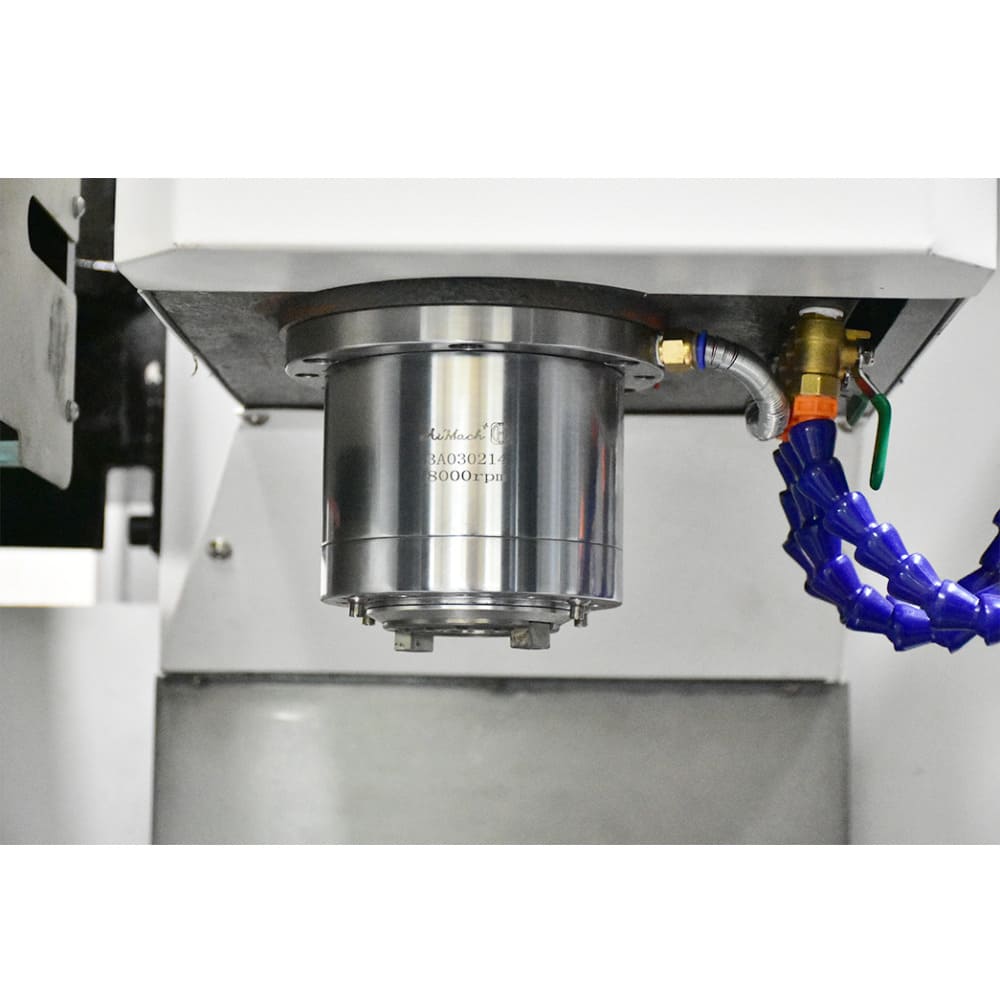

- Taiwan’s famous high-speed spindle, 8000, 10000rpm speed available.

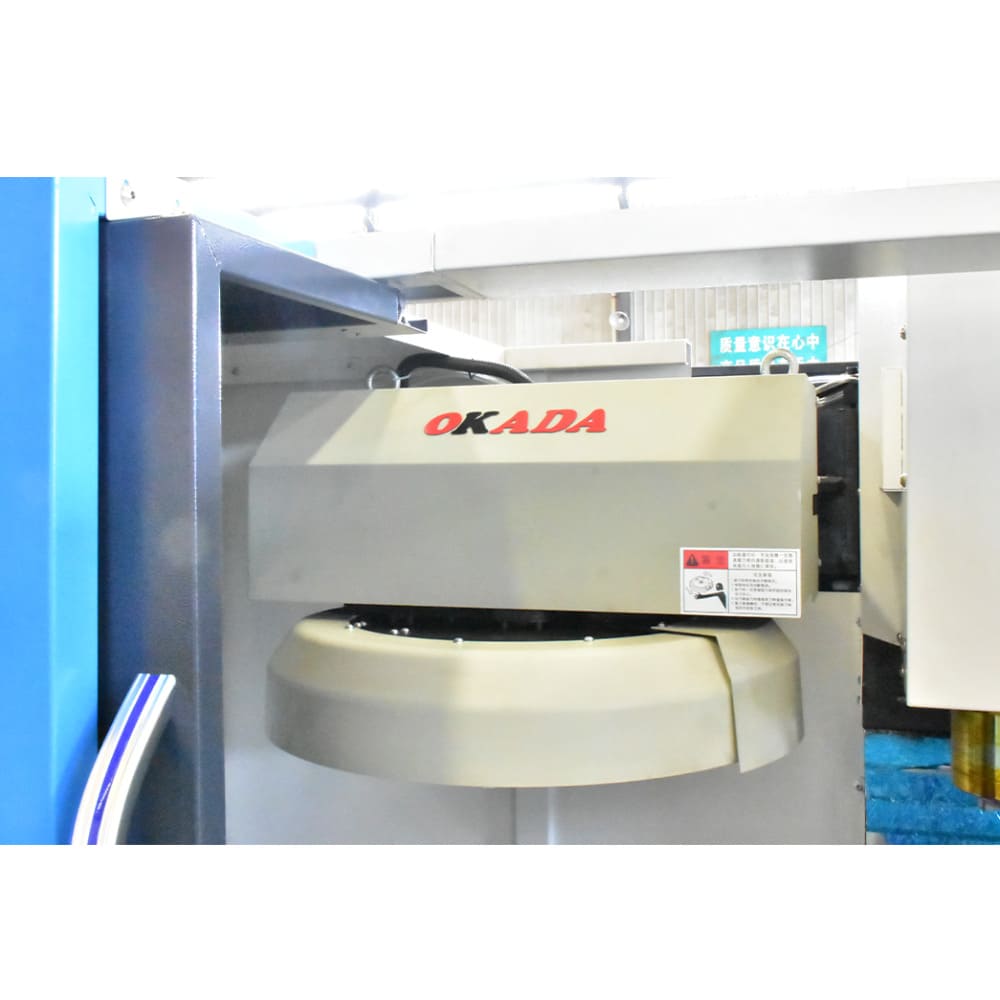

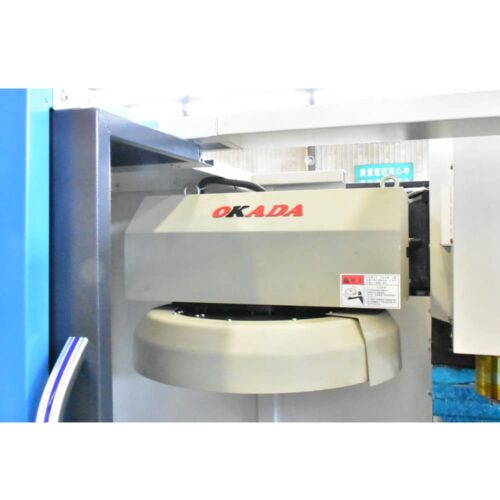

- Taiwan OKADA umbrella type 10T/12T ATC can be chosen.

- Reliable control system: Fanuc, Siemens, Mitsubishi, GSK.

- Systems can be selected according to customer requirement

- Automatic central lubrication system.

- Full protection

- Umbrella type 12T magazine tool Taiwan VOLIS spindle

- Three-axis lubricating system

- Separate hand-wheel

- Machine tool lighting work light

- Random technology document

- Spindle cone Hole cleaning air

- Electric cabinet cooling and heat exchanger

- Cleaning air gun

- Chip storage tank

- Servo transformer

- Foundation pad iron and adjusting bolt

CNC Vertical Machining Center Video

Advantages Of 4 Axis CNC Vertical Machining Center

- The fuselage and main components are high-strength cast iron and microstructure stability. It can ensure the stability of the machine tool for long use.

- The column at the bottom of A type bridge type structure, combined with the big box base. It greatly reduces the vibration of the machine on heavy cutting.

- Pre-tension precision ball screw drive.

- The VMC machining center has high speed, high precision, high rigidity spindle unit

- Design of oil-water separation.

- The intermittent automatic lubrication

- Automatic scraping knife system

- Taiwan’s famous principal axis, axial, and radial bearing capacity is strong. The speed of up to 8000rpm.

- Guideway, screw of the sealed protection, guarantee the screw and guide rail. It can ensure the clean, transmission, and movement precision of the machine tool.

- Electromagnetic valve group by PLC program control. It can ensure the spindle loose tools, spindle center blowing, spindle folder tools, air cooling spindle, etc.

-500x500.png)

Reviews

There are no reviews yet.