Product Video Display

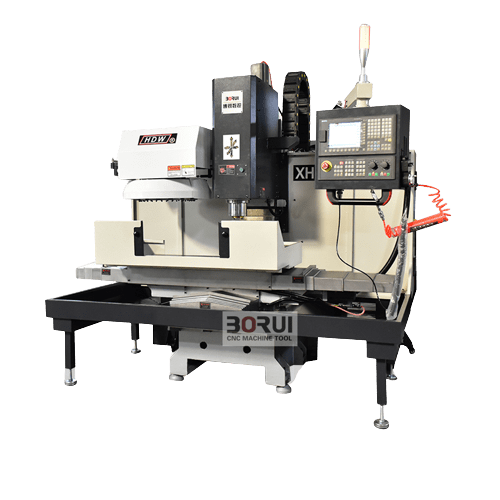

Technical Parameters Of BR600 CNC Drilling And Tapping Machining Center

| Product name | Drilling and Tapping Center | |||

|---|---|---|---|---|

| Model | Terms | BR—600 | BR—700 | |

| X-axis Travel | mm | 600 | 700 | |

| y-axis Travel | mm | 400 | 400 | |

| Capacity | Z-axis Travel | mm | 350 | 350 |

| Spindle nose to table surface | mm | 135-485 | 135-485 | |

| Spindle | Spindle Speed | rpm | 20000/2400 | 20000/2400 |

| Tool storage capacity | PCS | 16/21 | 16/21 | |

| Max.tool diameter (adjacent tools) | mm | 50(120) | 50(120) | |

| A.T.C | Max tool length | mm | 250 | 250 |

| Max tool weight | kg | 3 | 25 | |

| Tool change time(T-T) | sec | 1.6 | 1.6 | |

| Motor | Spindle power (30-minute stop-motion) | kw | 3.7/5.5 | 5.5/7.5 |

| X/Y/Z-axis motor power | kw | 1.5/1.5/3.0 | 1.5/1.5/3.0 | |

| Worktable | Table size | mm | 700x420 | 700x420 |

| Table T slot size (No. - width) | mm | 3*14*125 | 3---18 | |

| Worktable-Loading | kg | 300 | 300 | |

| Fast Rapid | X-axis fast rapid | m/min | 48 | 48 |

| Y-axis fast rapid | m/min | 48 | 48 | |

| Z-axis fast rapid | m/min | 48 | 48 | |

| Cutting feed rate | Mm/min | 5-20000 | 5-20000 | |

| Accuracy | Positioning accuracy | mm | ±0.003/300 | ±0.003/300 |

| Repeatability positioning accuracy | mm | ±0.005/300 | ±0.005/300 | |

| Machine size | Weight | kg | 3500 | 4500 |

| Power demand | KVA | 20 | 20 | |

| Overall Size | mm | 2220X1900X2300 | 2320X1900X2300 | |

| Tank capacity | L | 210 | 210 | |

| Compressed air | Kg/m2 | 6--8 | 6--8 | |

Features Of BR600 CNC Drilling And Tapping Machining Center

1. FANUC-31I CNC System with The Strongest Performance

The ANUC-31I CNC system has high performance, stability, and efficiency. In the three-dimensional processing process, if the unit accuracy is set to 0.001mm, the processing program’s capacity will be several times higher than the capacity of the original program. This is only possible with a high-performance and high-speed CNC system. Most of the drilling and milling centers on the market still use the low-level FANUC-0iMC CNC system. We will inevitably be unable to process data. The FANUC CNC system is relatively popular in the market.

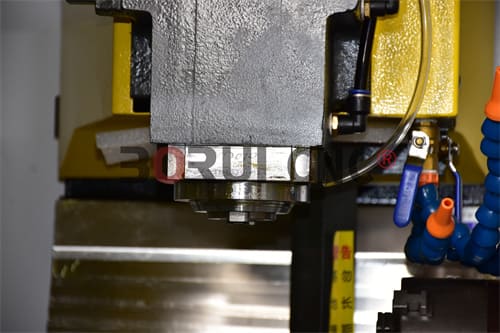

2. High Rigidity Spindle

- Whether a 10000 rpm or 24000 rpm spindle, it is 11Kw/3.7Kw (1 point rated power/continuous rated power). The spindle of the FANUC machine tool can perform rigid machining actions in a short time. Such as rough milling and boring. It is beyond the reach of other Japanese brand machining centers! The spindles of other brands are generally 5.5Kw/3.5Kw.2)

- It is a direct connection structure between the motor and the spindle. That is a direct-coupled spindle.3)

- The BR600 uses grease-loaded bearings. It can be used for a long time and does not require frequent maintenance.

- The high-speed spindle adopts high-speed and high-precision bearings with low heat generation.

- It is a spindle with high torque specification. Torque in the low-speed area increases by 32%, from 53Nm to 70Nm.

3. High Acceleration Positioning

High-speed control, optimal torque acceleration, and deceleration control. All three axes can reach a high acceleration of 1.3G. The higher the acceleration, the faster the reaction speed of the machine tool. Adjust the movement direction to move the shorter the time.

4. High Precision And High Stability

- The ultra-high-resolution pulse encoder performs interpolation and feedback in nanometers. The minimum precision unit can be set to 0.0005mm.

- Nano Interpolation, AI Contour Control II (Option), Shock Control (Option), NURBS Interpolation (Option), Nano Smoothing (Option), Fast Data Server (Option).

- It has a high-reliability mechanical structure. Most customers of FANUC machine tools work 30 days a month × 24 hours for a long time. The machine tool can keep the accuracy stable, and the failure rate is meager!

5. AI Thermal Displacement Compensation Function

The standard configuration of the three-axis AI thermal displacement compensation function. It compensates for the thermal displacement caused by the movement of the main shaft and the feed axis. It can ensure high machining accuracy.

6. AI Contour Control II, HRV Control

Extremely smooth machined surfaces can be achieved with AI Contour Control II. It is rigorous in the processing of consumer electronics!

7. Robot Automated Production Line

FANUC itself also produces manipulator products. The numerical control system uses the FANUC system. There is no problem with product compatibility. Whether a small processing unit or a large-scale assembly line, it is easier to be compatible with and convenient.

8. 4-axis/5-axis Simultaneous Machining

FANUC small machining center is one of the manufacturers with four/five-axis linkage machining technology in the market. Most of the other competitor brands’ drilling and milling center machines are fake four/five-axis machining. They need help to achieve four/five axes.

Product Image Display

Applications of CNC Drilling And Tapping Center

CNC drilling and tapping machining centers can achieve multi-face and contour machining in milling, boring, and side cutting. Three-dimensional machining of resin models, electrodes, precision parts, and molds with high speed and high precision. It is suitable for high-speed cutting of light metals such as aluminum to processing electrical appliances and small parts of stainless steel. It can also deburr and chamfer magnesium injection molded parts, die-cast parts, forged parts, etc.

It has unique advantages in CNC processing speed and three-dimensional processing! Especially the copper electrode processing of mobile phone molds has an overwhelming advantage! Its cost performance is unmatched by other Japanese high-speed machines: high-performance stability and less failure. The fast data processing speed produces high efficiency and surface quality (especially surface finish). It is widely used in communications, IT, auto parts, electronics, digital products, machining, and other fields.

-500x500.png)

Reviews

There are no reviews yet.