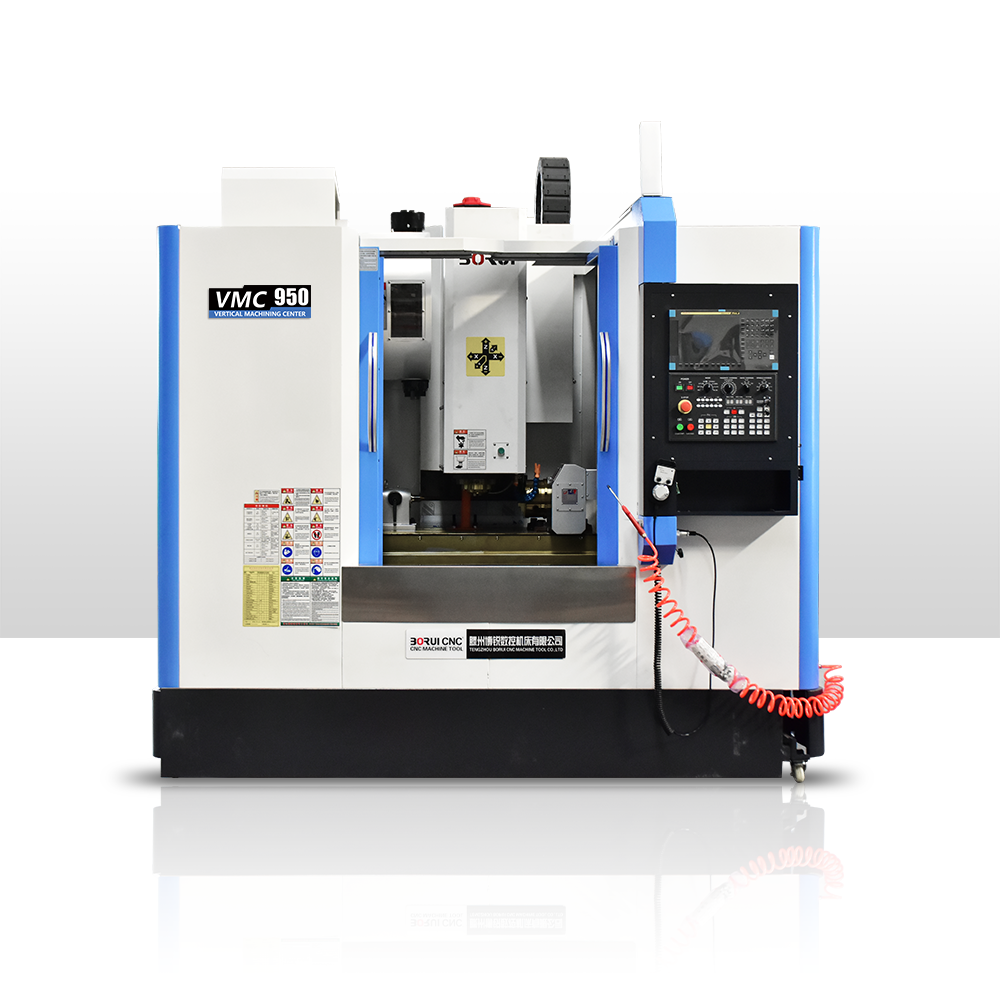

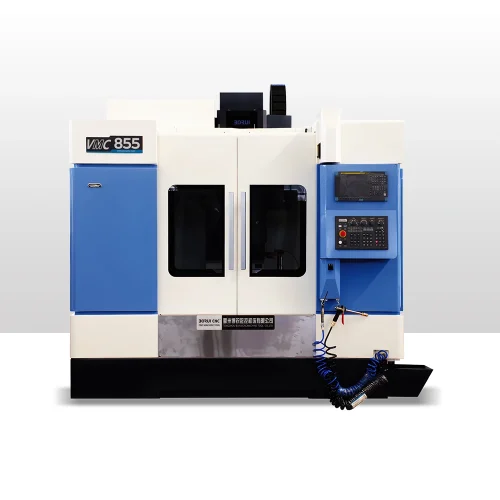

Features of CNC Vertical Machining Center VMC950:

- The body adopts three-dimensional variable diameter structure design to ensure the stability and reliability of the body, prevent deformation of the body, and increase the service life of the machine tool.

- The sliding seat of the machine tool adopts a box-type design, and the dense reinforcement ribs are arranged inside the box, which doubles the accuracy of the machine body.

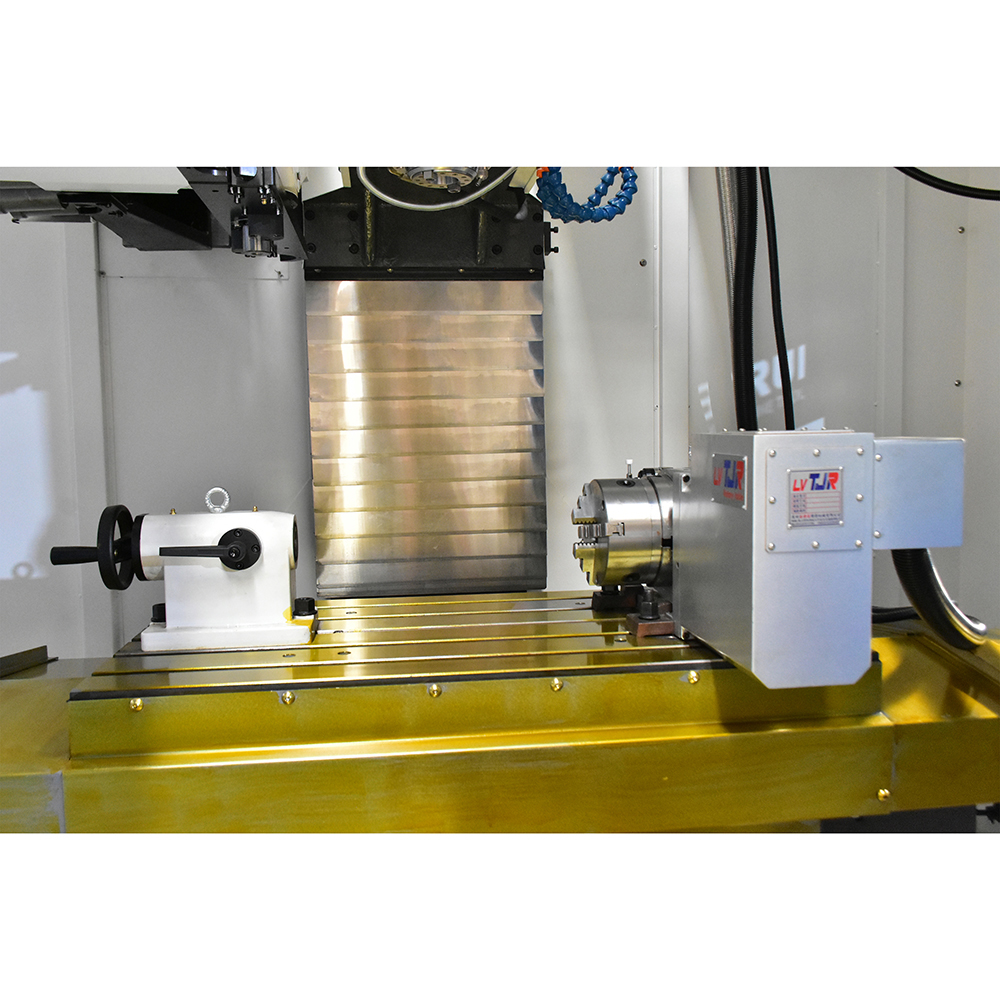

- The machine tool table adopts a double-layer reinforced design, and the increase in the thickness of the table effectively hides the interference of the installation of the linear guide sliding seat on the table, and further enhances the rigidity.

- The XYZ axis guide rails of the machine tool all adopt the method of large span ratio, which increases the weight of the machine tool as a whole, thereby improving the stability of the machine tool.

- The ball screw nut of the machine tool is an elongated design, and the pre-tightening force of the nut has been effectively improved, which greatly prolongs the service life of the machine tool and the retention of precision.

- The ball screw of the machine tool adopts a pre-configured locking nut structure, which can effectively prevent the locking nut from loosening.

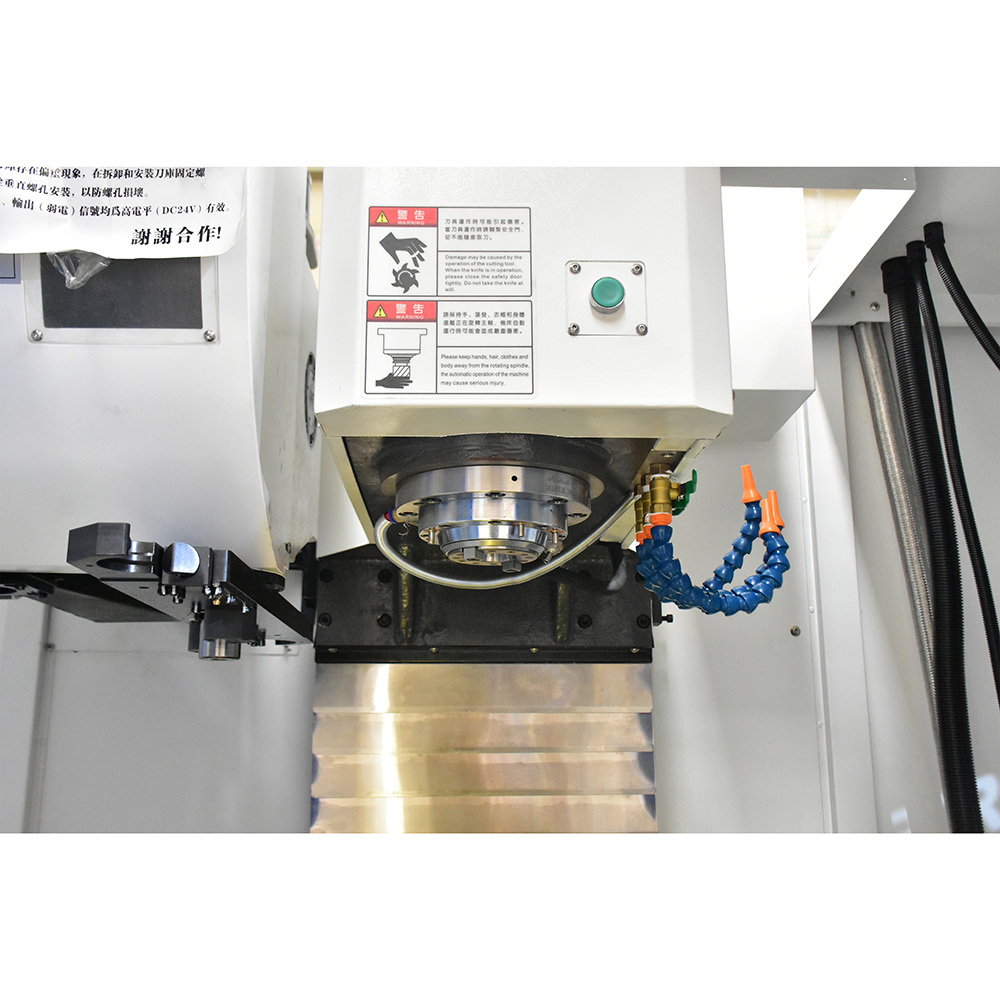

- The machine tool adopts our own active lubrication system, and the oil pump is directly controlled by the numerical control system, which truly achieves oil filling on demand, and can sense the problems caused by the oil circuit of the machine tool and give customers an early warning in time to prevent the machine tool from being damaged.

- The machine tool adopts the inner protection design of the supporting pulley block, which is not easy to deform and has a long service life.

- Each machine tool must precisely match the weight of the Z-axis counterweight according to the customer’s purpose. Targeted optimization of the problem between the machine tool and the product made by the customer.

Technical parameters of CNC Vertical Machining Center VMC950:

| Specification | VMC950 | |

|---|---|---|

| X axis travel | mm | 900 |

| Y axis travel | mm | 500 |

| Z axis travel | mm | 600 |

| The distance from spindle nose to worktable surface | mm | 150-750mm |

| The distance from spindle center to column surface | mm | 560 |

| T-slot | mm | 3-18*130 |

| Worktable size | mm | 1000*500 |

| Worktable max loading | kg | 600 |

| Spindle speed | rpm | 8000 |

| Main motor | kW | 7.5 |

| spindle taper | BT40(Φ150) | |

| Rapid traverse speed | m/min | 24/24/20 |

| Cutting feed speed | mm/min | 1-10000 |

| Three axis Servo motor | kW | 2 * 2 *3 |

| Magazine tool capacity | pcs | 24(disc type) |

| Machine overall size | mm | 2400*2300*2580 |

| Machine weight | kg | 6000 |

-500x500.png)

Reviews

There are no reviews yet.