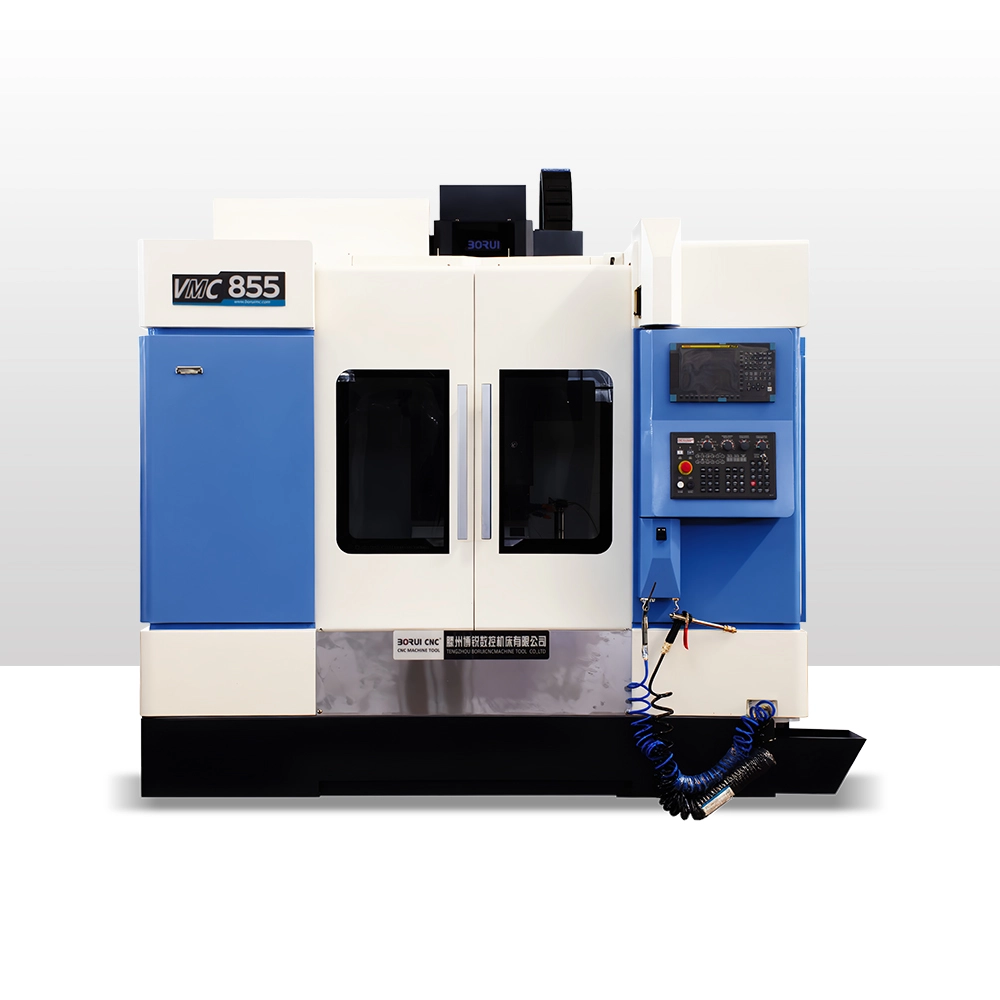

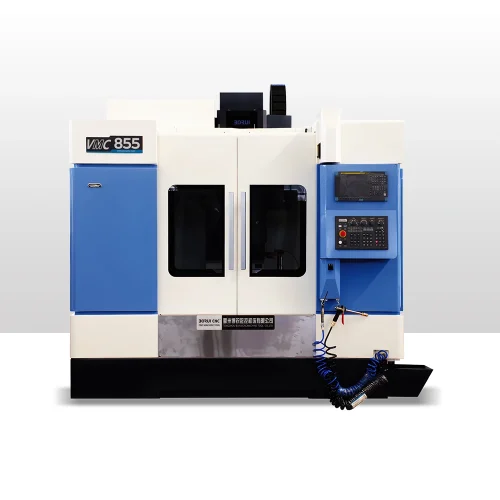

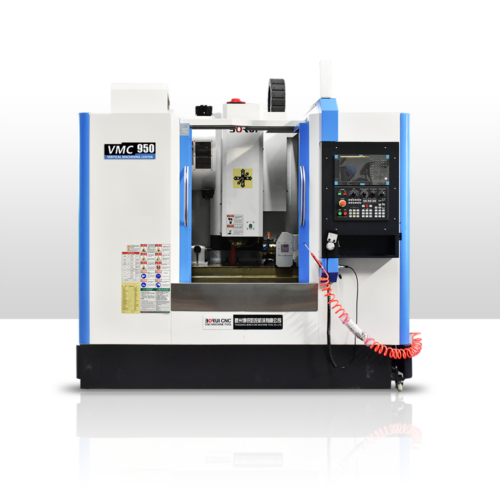

VMC Vertical Machining Center Features

- Resin sand casting

- Taiwan HIWIN linear guide

- Vertical frame layout

- Systems can be selected according to customer requirement

- SYSTEMCNC CONTROL

- SIEMENS, KND, FANUC, Mitsubishi, GSK, and other operating

- Full protection

- High-hardness bed castings

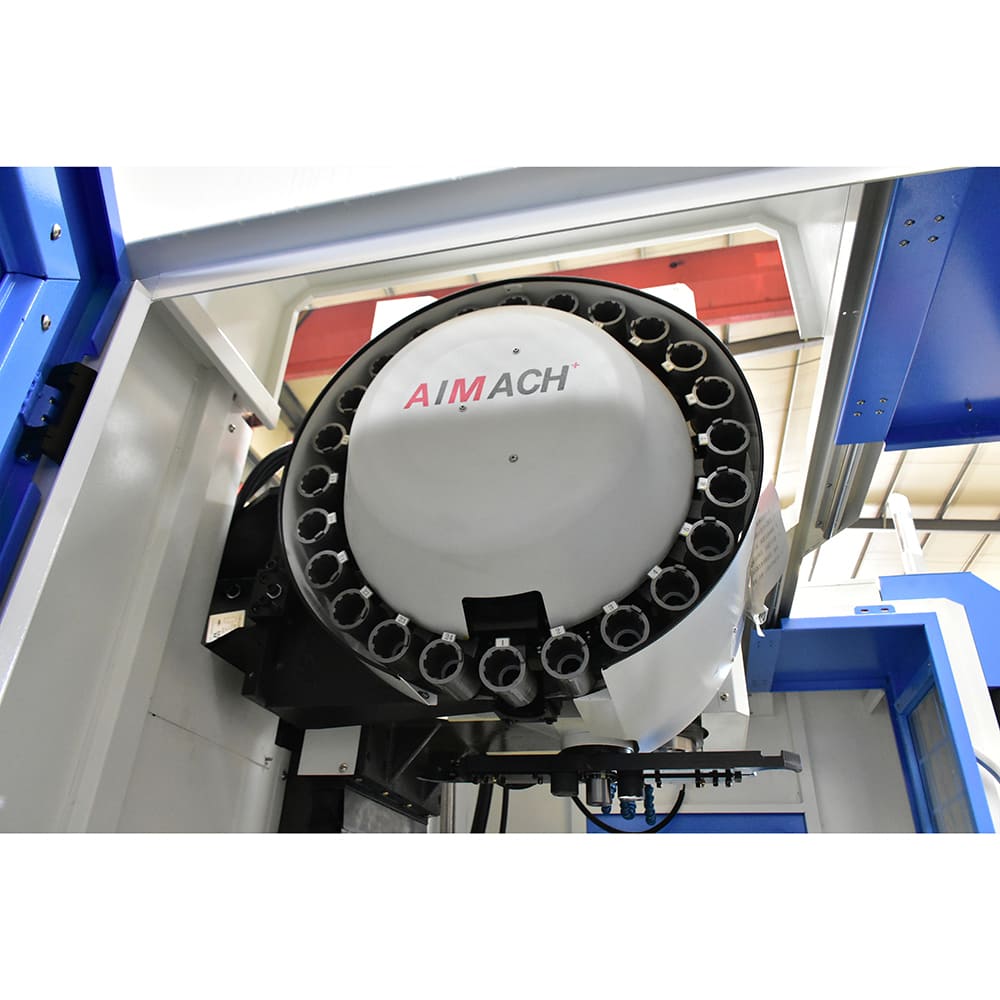

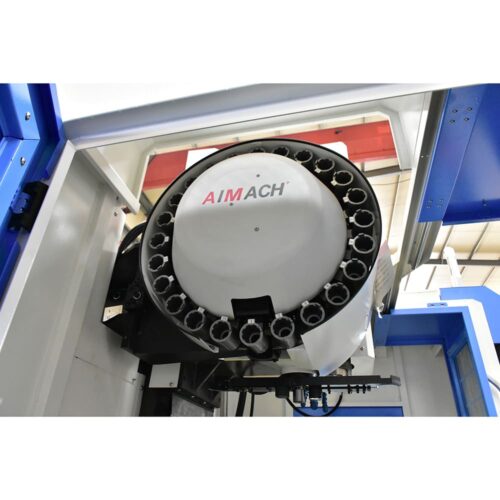

- 24 Disc ATC

- Taiwan VOLIS spindle

- Spindle speed 8000 / 10000 / 12000

- The spindle is stepless in its speed range

- Three-axis lubricating system

- Separate hand-wheel

- Machine tool lighting work light

- Random technology document

- Spindle cone Hole cleaning air

- Electric cabinet cooling and heat exchanger

- Cleaning air gun

- Chip storage tank

- Servo transformer

- Foundation pad iron and adjusting bolt

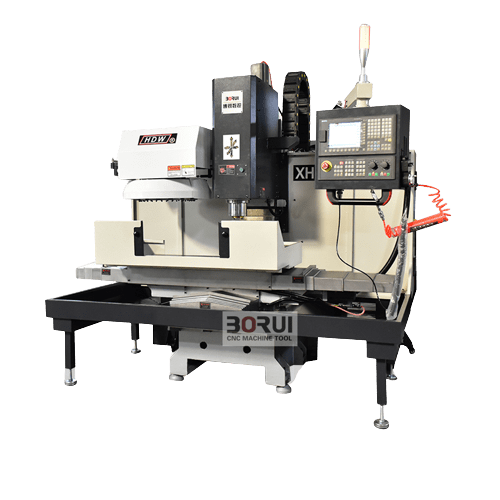

Advantages of VMC855 5 Axis Vertical Machining Center

- The casting adopts a new HT300A+ casting formula. Cast in resin sand, tempered. Vibration and natural aging treatment to eliminate internal stress.

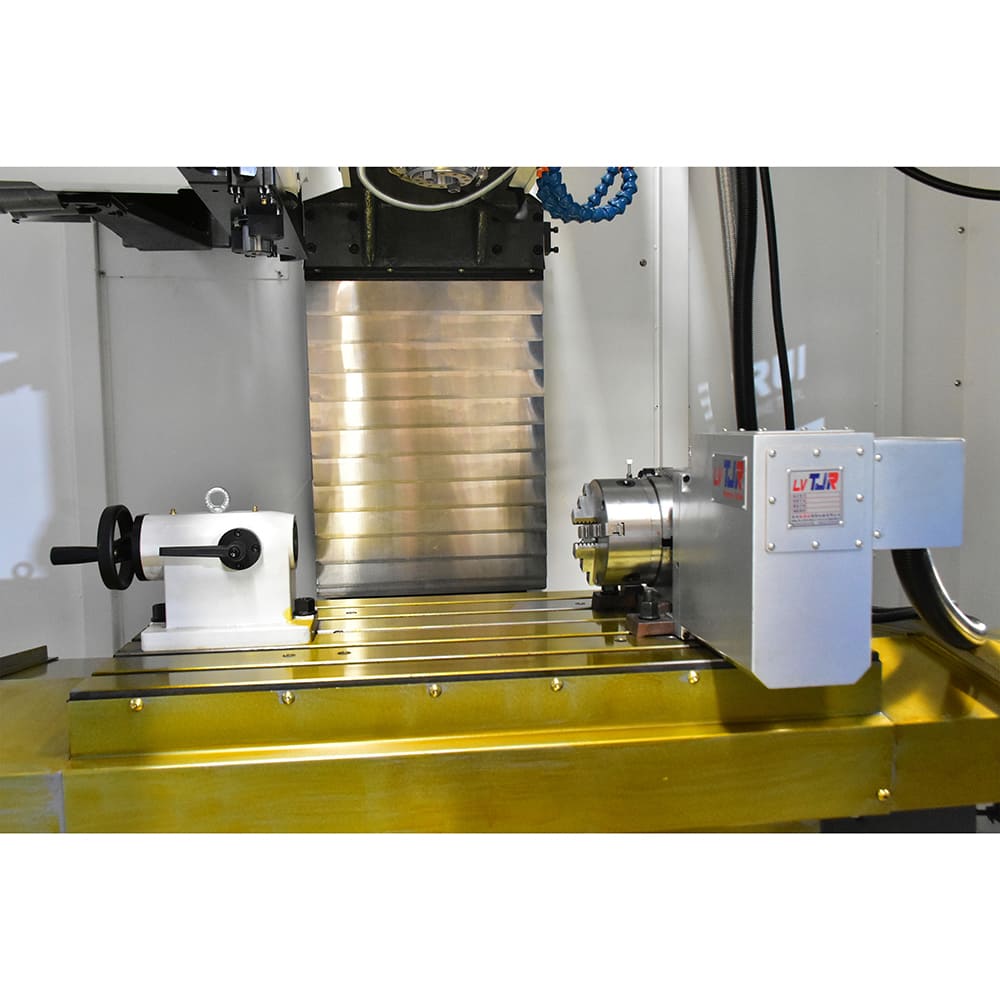

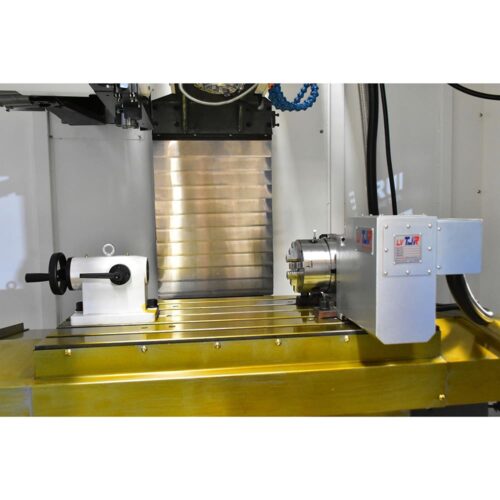

- The 5 axis cnc vertical machining center uses an integrated upper water guide plate type wide base. The five large parts are mesh internal structures.

- The bottom uses the super wide “man” shaped column. Body oil and water separation structure (front water after oil), hidden pipeline.

- The 5 axes are roller type. The roller type will be more durable than the commonly used market ball type. Because of the larger contact surface, so more stable, and heavy cutting.

- The 5 axes all adopt Taiwan PMI or HIWIN linear lead screw guide rods. This can better ensure the precision and stability of the machine tool.

- Five axis rapid displacement up to 48 meters. This can improve the processing efficiency!

- The machine can be installed with four axes and five axes. Multi-sided one-time processing improves production efficiency.

- 24 disk tool library, free tool change. Tool change speed of 1.9 seconds. This can ensure the stability of the tool library.

Reviews

There are no reviews yet.