There are a lot of different kinds of band saws that you can use for cutting and making things. Each type of band saw can handle a different set of tasks. Ensuring you use the suitable band saw for the job will improve safety, speed up work, and result in a better cut. You could…

A flatbed CNC lathe is mainly used for heavy-duty turning and can make discs, short shafts, and complex shapes. It can also make different internal and external metric or imperial values threads. When put on the flat bed CNC machine, the rotary head can mill or drill the workpiece’s edge and around its edge. The…

By its tool magazine, you can tell if a computer numerical control (CNC) machine is a CNC machining center or a CNC milling center. A CNC, or computer numerical control, lathe is an automated machine that has a method for controlling programs. When the control system reads the program, it might use control codes or…

Circular saws and band saws are two standard tools when it comes to the world of woodworking and metalworking. They play a unique role in cutting materials. Both saws have their unique designs and features. They can exert different advantages in different work scenarios. But if you had to choose, would you prefer a circular…

In the modern world of manufacturing and engineering, CNC machines are indispensable tools. Computer programs control them. They can complete high-precision and high-efficiency processing tasks. The same CNC machine type shows unique advantages when processing parts of different materials and shapes. It can meet the needs of the manufacturing industry for efficient, precise, and diverse…

Regarding innovation and efficiency in modern manufacturing and engineering, CNC machine tool centers are a critical element that cannot be ignored. CNC machine tool centers have become a revolutionary technology in the manufacturing industry. It brings a whole new dimension and efficiency to the production process. In this article, we’ll take a closer look at…

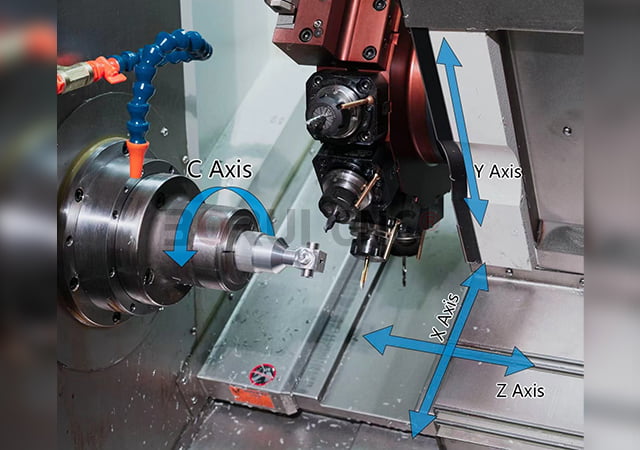

With the continuous development of science and technology, CNC lathes play an important role in modern manufacturing industry. As an important part of CNC lathe, Y-axis has an important influence on its performance and function. This paper will discuss the benefits of Y-axis to CNC lathes, including improving machining accuracy, increasing machining range,…

In the modern industrial field, High-speed Machining Center (CNC high-speed machining center) is widely used in the key role of improving precision machining efficiency. CNC high-speed machining center with its high-speed, efficient characteristics, become the industry’s star products. Like a shining star on the stage, CNC high-speed machining centers shine brightly in the…

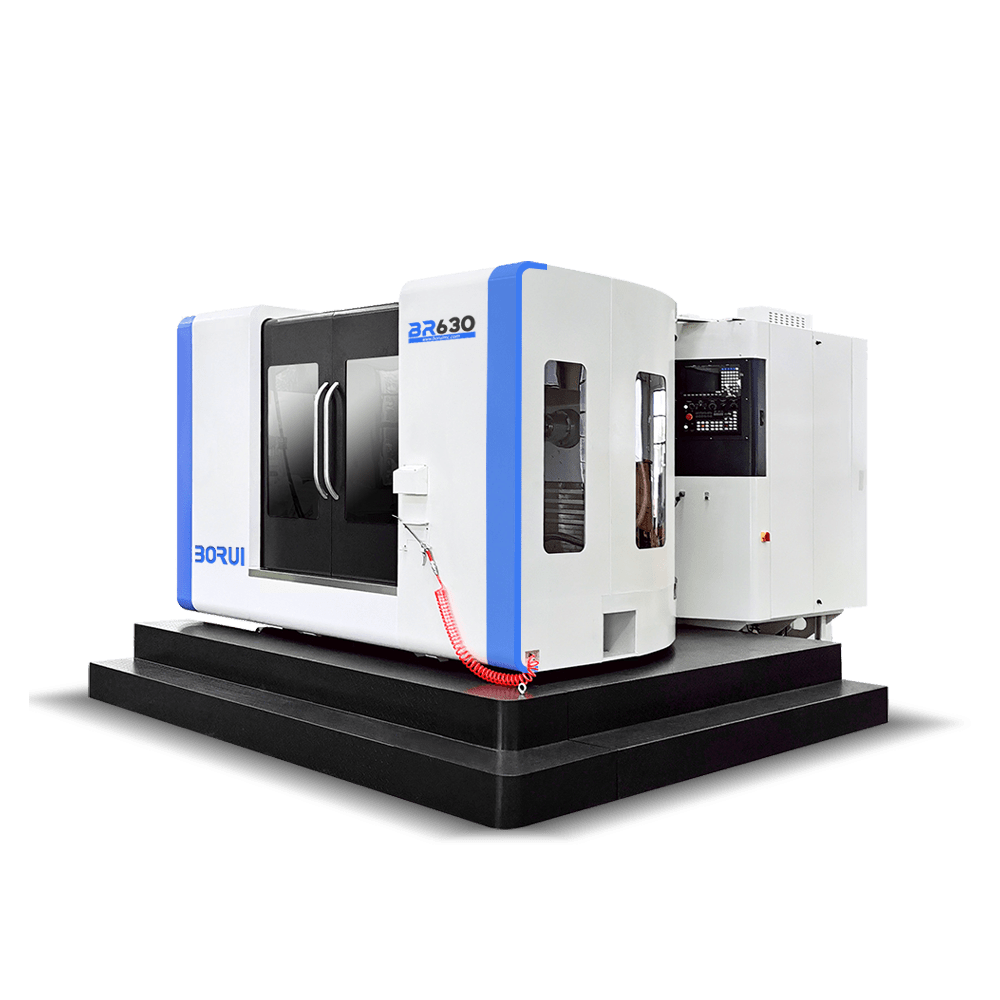

What Is Horizontal Machining Center The horizontal machining center, like a smart craftsman, quietly injects vitality into the manufacturing industry. It is an important tool for modern industrial manufacturing and has injected strong power into the production line. First, let’s take a look at its appearance. Horizontal machining center is like…

What Is A CNC Machine ? CNC machine tool is a kind of high-precision and high-efficiency automatic mechanical equipment, which realizes the workpiece processing through the computer control system. Compared with traditional machine tools, CNC machine tools have higher accuracy, faster processing speed and greater production capacity. The emergence of CNC…