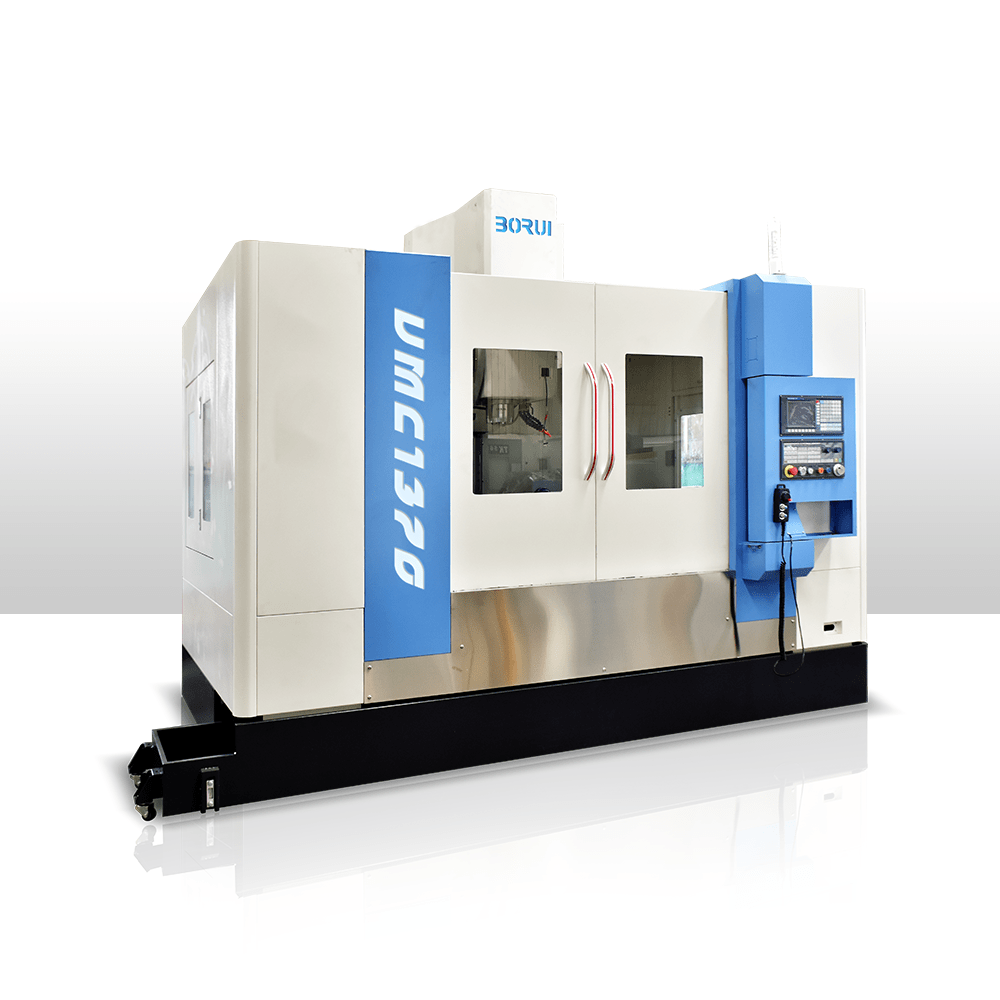

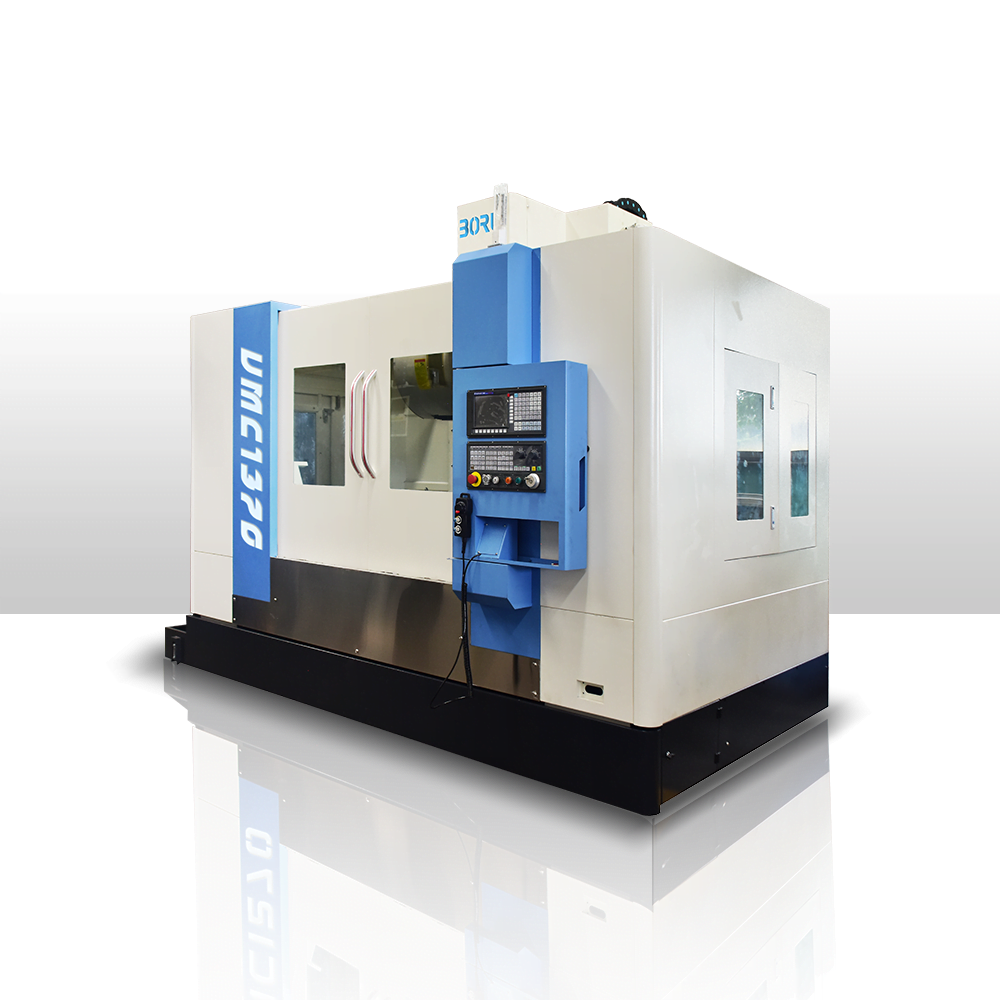

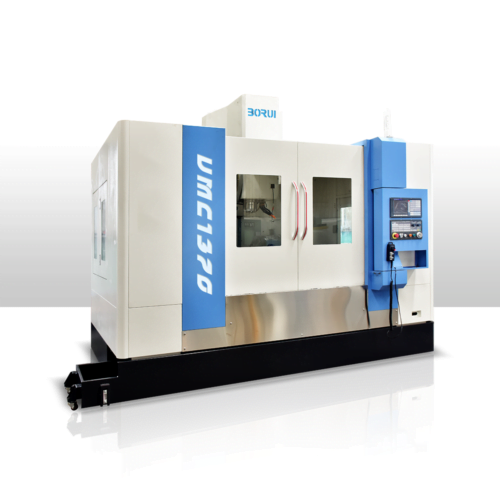

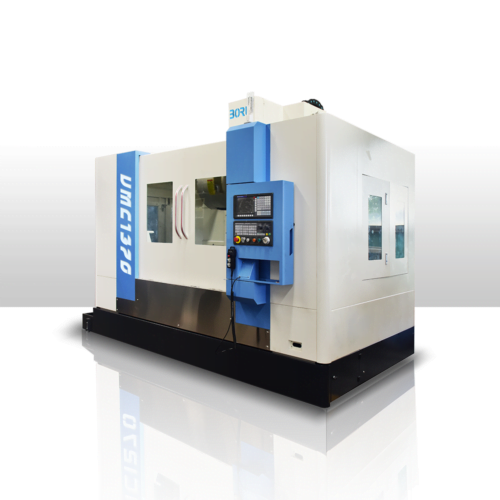

Features of large vertical machining center VMC1370:

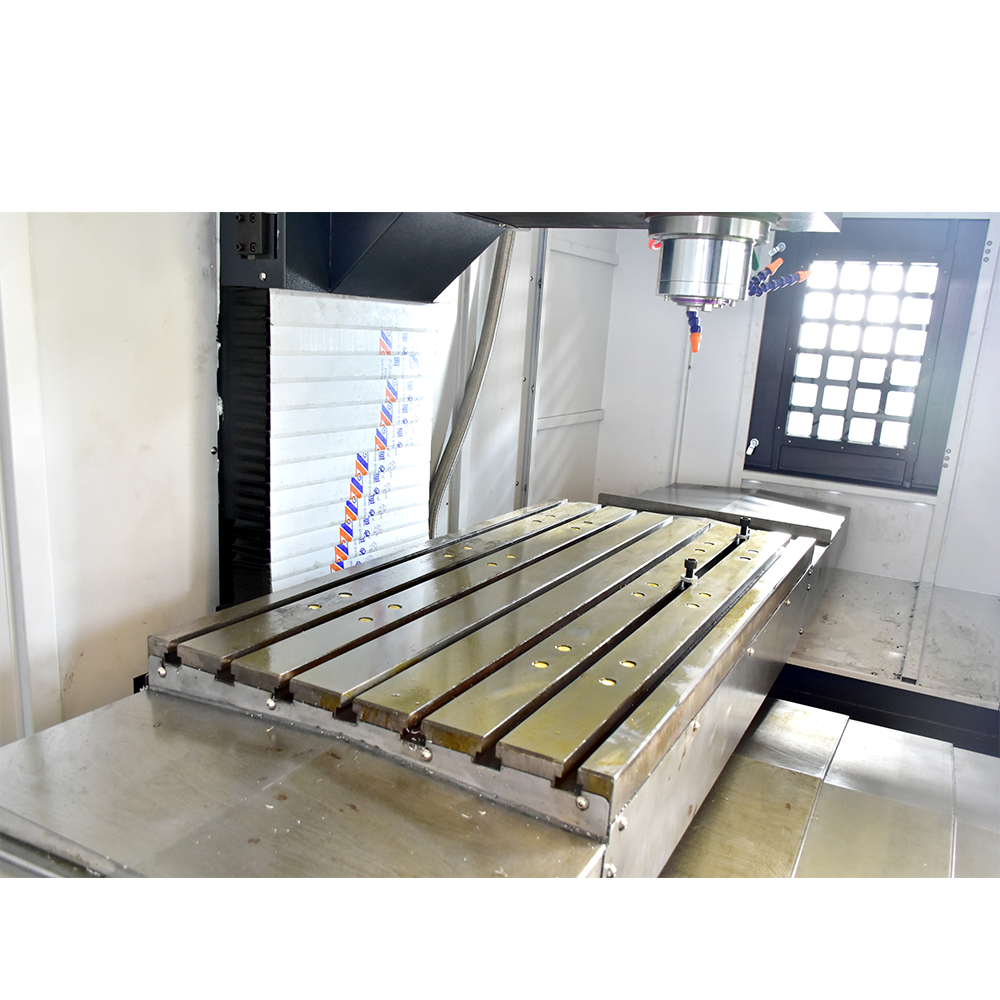

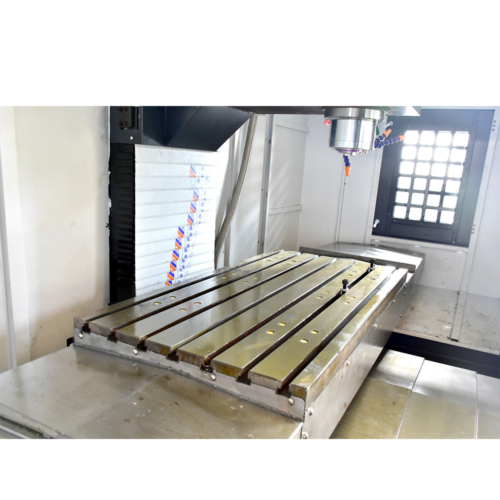

- Choose ball screw, wire gauge with automatic centralized lubrication device to reduce friction resistance and stable operation.

- The three-axis feed is supported by Taiwan high precision ball screw with high precision and good bearing performance.

- Ensures the positioning accuracy and repeated positioning accuracy of the machine tool.

- P4 main shaft bearing and concentrated grease lubrication are adopted.

- It is assembled under constant temperature conditions and has passed balance correction and running test by computer. It has stable operation and long life.

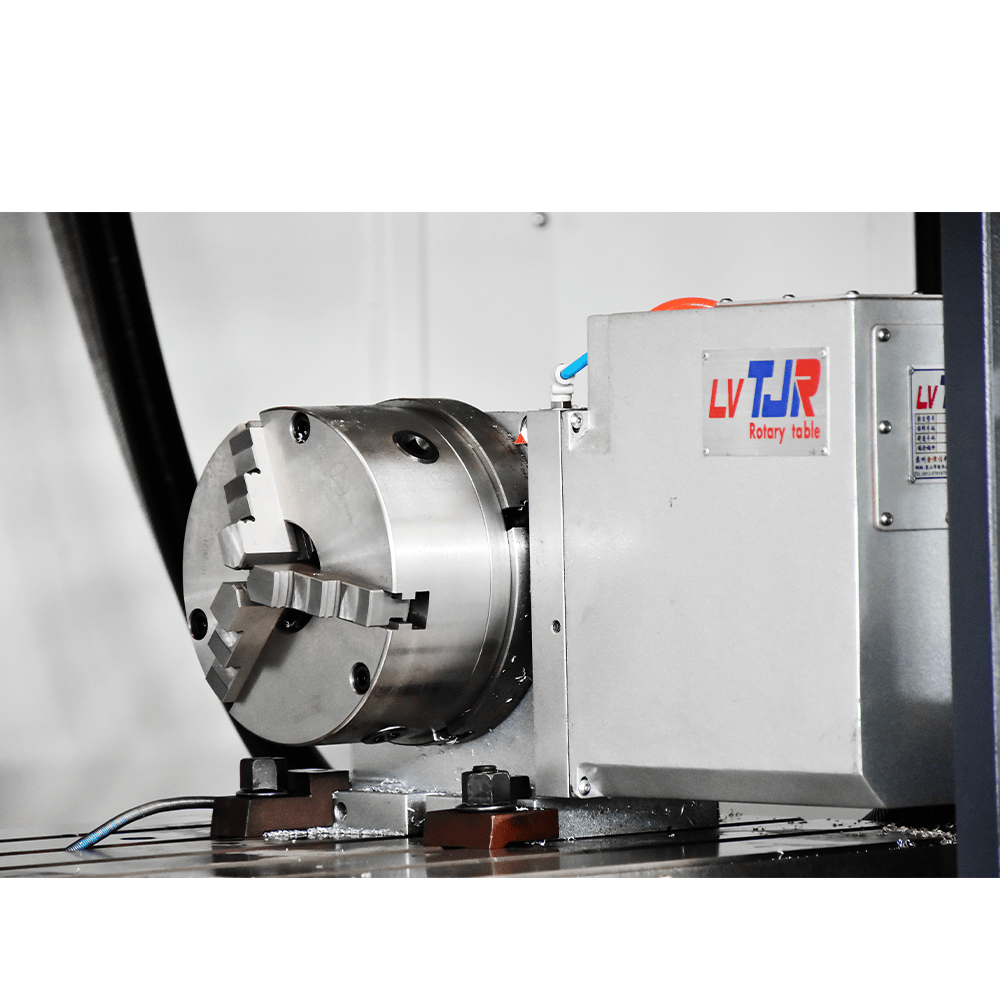

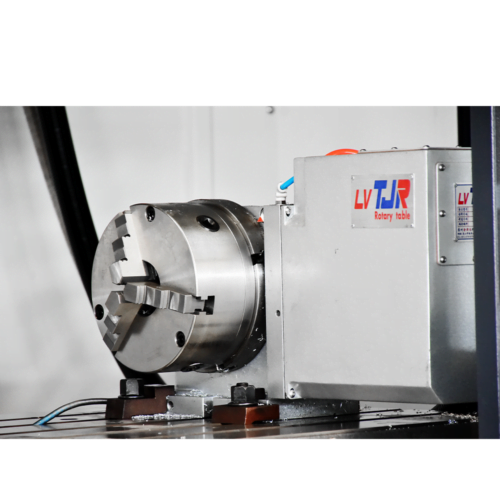

- A number of brands of CNC system optional, good stability, read program speed.

- Choose brand copper core servo motor, accurate control, stable operation.

Technical Parameters Of VMC1370 CNC Vertical Machining Center:

| Model | Unit | VMC1370 |

|---|---|---|

| X axis travel | mm | 1300 |

| Y axis travel | mm | 700 |

| Z axis travel | mm | 700 |

| Spindle nose to table surface | mm | BT40- ∮ 150:100-800;BT50- ∮ 155:70-770 BT50- ∮ 190:120-820 |

| Spindle center to Column surface | mm | 773 |

| Worktable Size(X-axis direction) | mm | 1400 |

| Worktable Size(Y-axis direction) | mm | 700 |

| T slot qty-width*distance | mm | 18x5x110 |

| Spindle specification | ||

| Spindle speed(Belt type) | rpm | 8000 |

| Main motor power | kW | 45245 |

| Spindle taper | BT40(BT50) | |

| X/Y/Z axis rapid feed | m/min | 24/24/24 |

| Cutting rapid feed | mm/min | 1-10000 |

| Three-axis servo motor power | kW | 3 X 3 X 3.5 |

| Tools capacity | pcs | Disc Type 24 |

| Machine length | mm | 3200 |

| Machine width | mm | 2540 |

| Machine high | mm | 2600 |

| Machine weigth | kg | 8800 |

-500x500.png)

Reviews

There are no reviews yet.