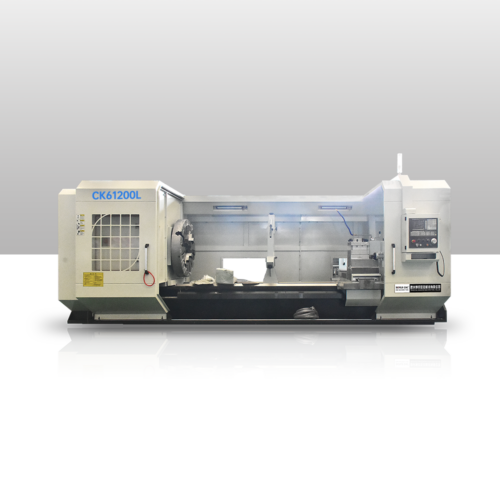

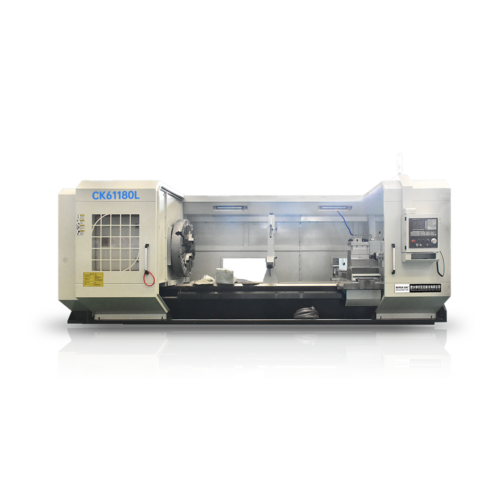

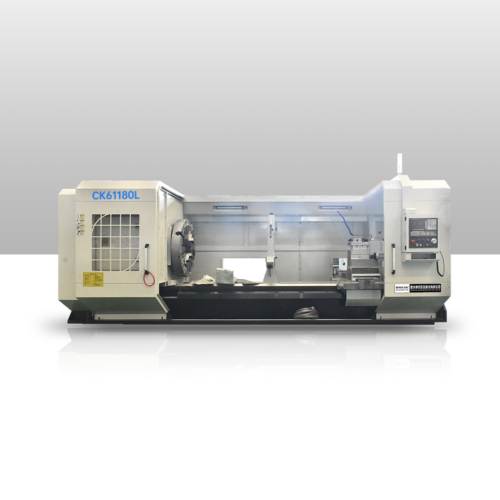

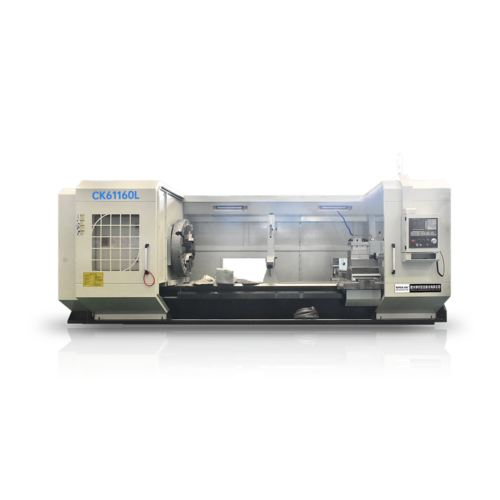

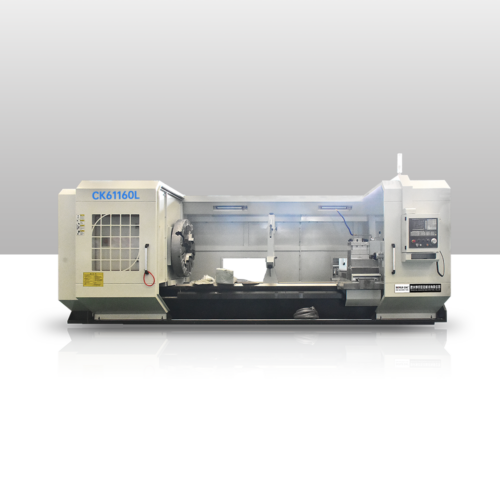

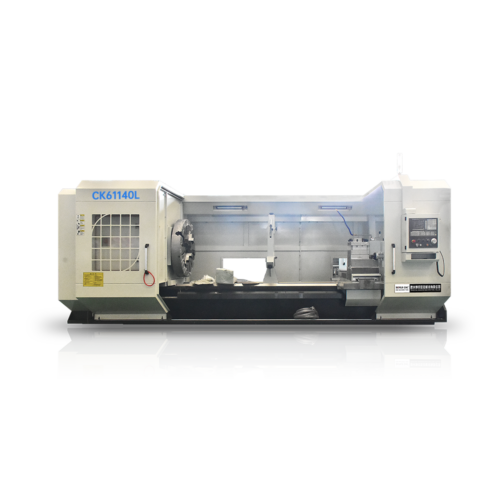

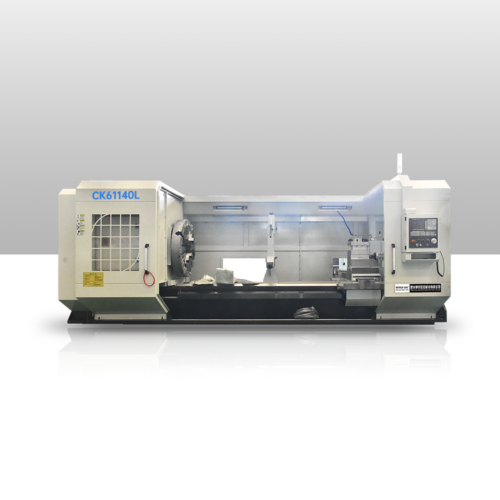

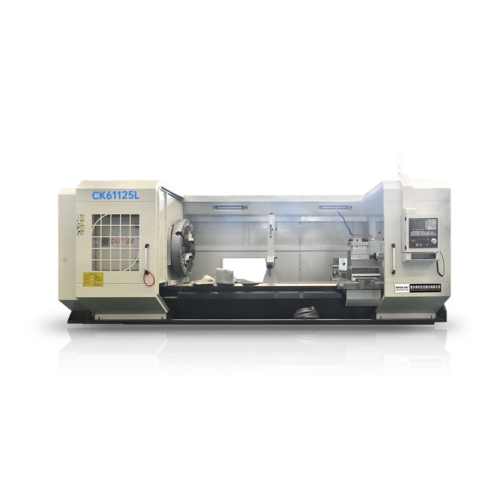

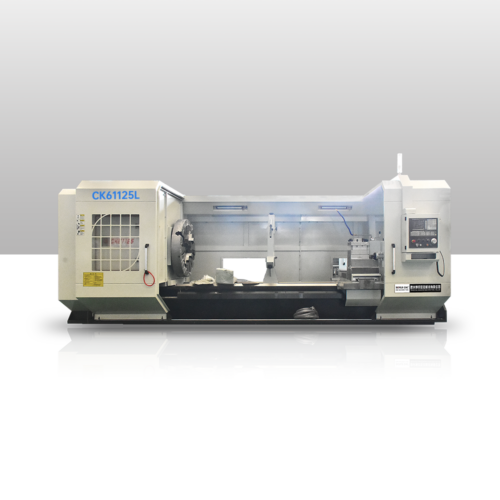

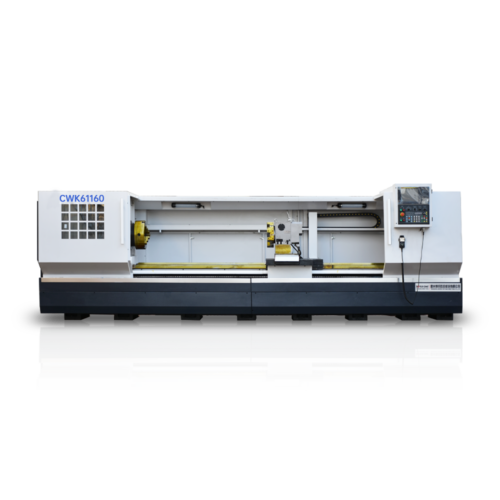

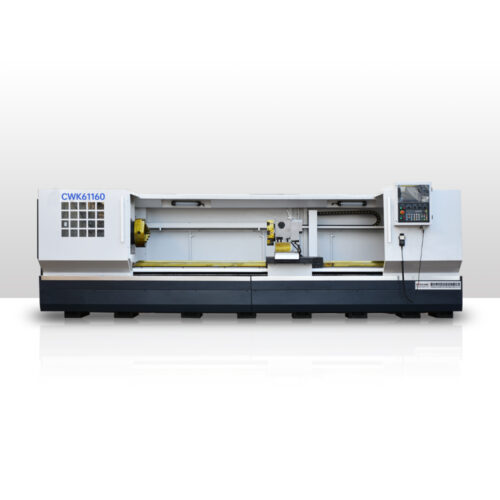

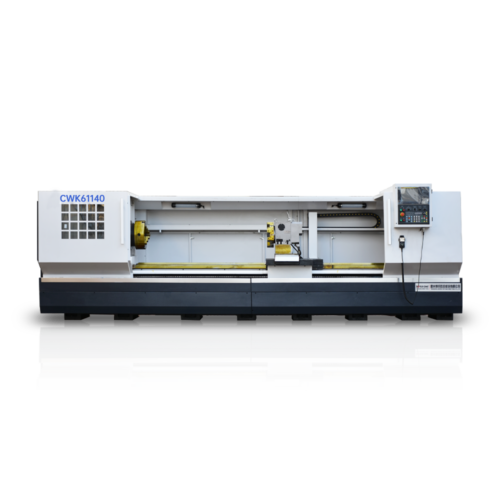

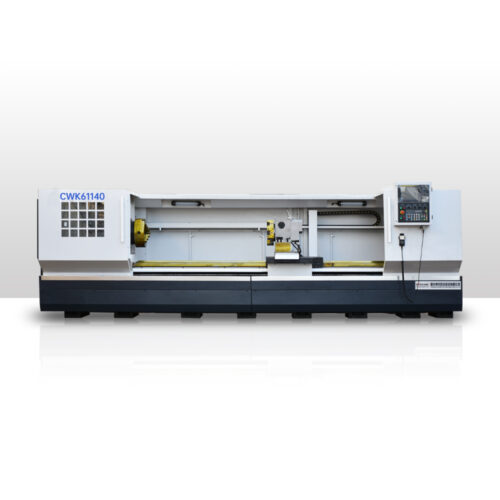

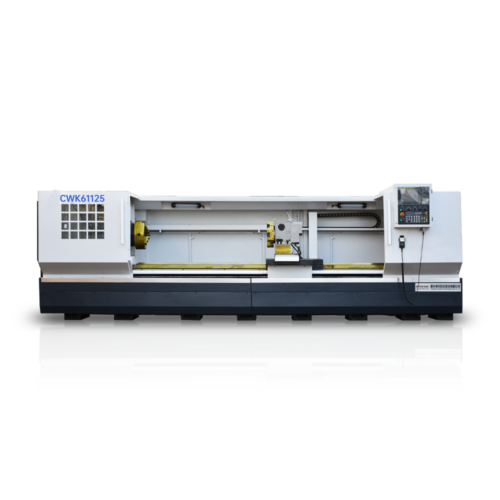

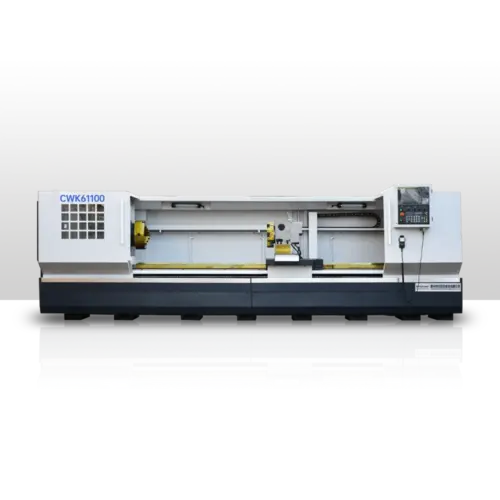

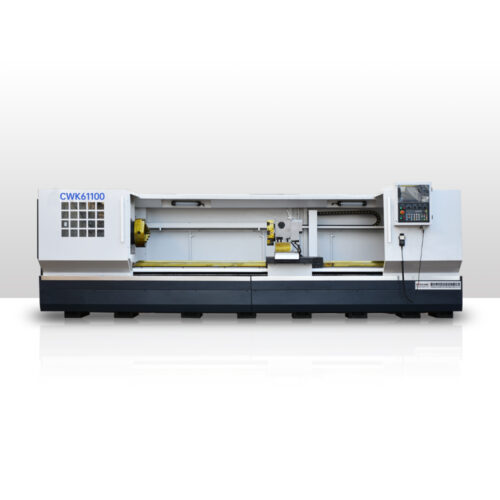

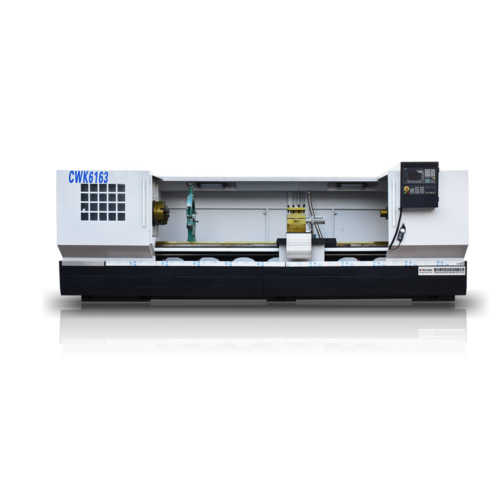

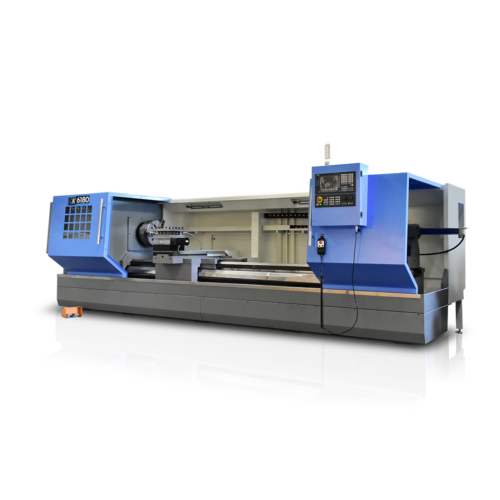

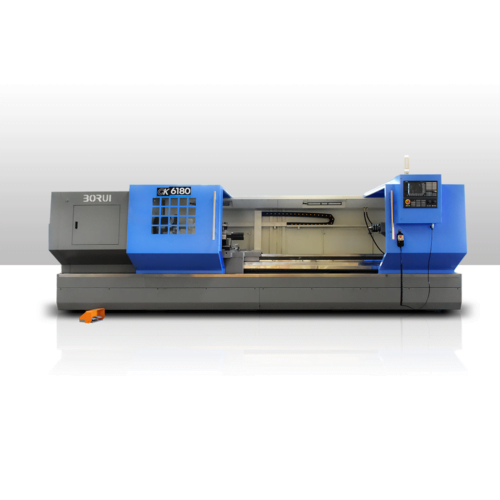

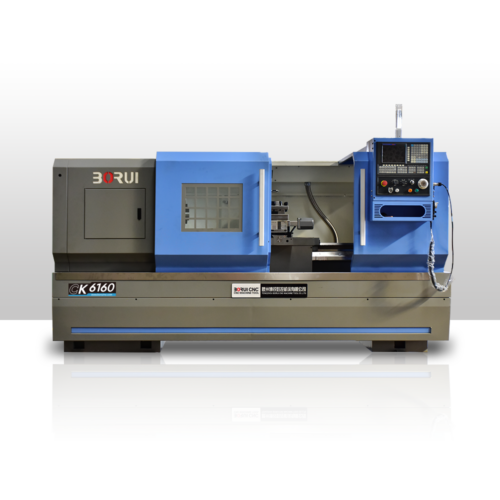

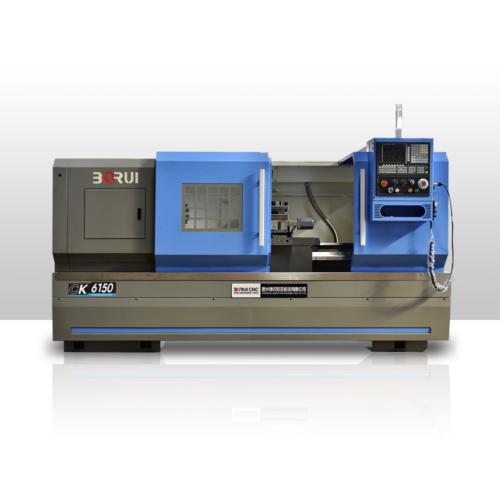

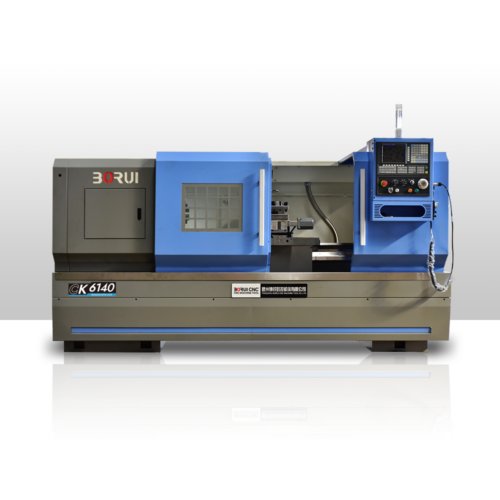

Flat Bed CNC Lathe Machine

Using Borui's flat bed CNC lathe can improve your processing capabilities. Our advanced technology is designed for accuracy and versatility. We ensure excellent results from our machines in a variety of applications. As a professional flat bed CNC lathe manufacturer, BORUI has many advantages. These advantages make us stand out from the competition in the market.

Request a Quote!Features of CNC Flat Bed Lathes

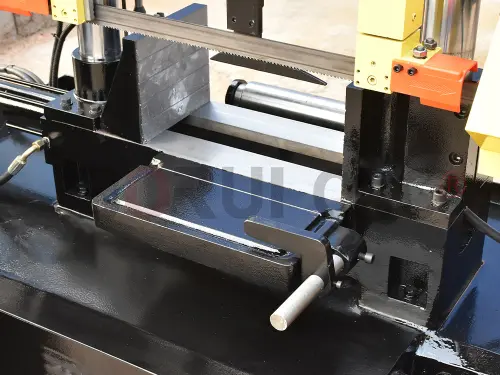

Flat Bed Structure

Flat bed CNC lathe has a flat bed, and the workpiece is fixed on the platform. This structure helps improve stability and rigidity. It is suitable for processing long and thin workpieces.

High Precision Machining

The flat bed CNC lathe machine can achieve high-precision machining. These include precision turning, milling, drilling, and other processes.

Multi-process Processing

CNC flat bed lathes have versatile processing capabilities. They can complete many processes on the same machine tool, improving production efficiency.

Suitable For Large Workpieces

Due to their flat bed structure, CNC flat bed lathes are suitable for processing large, long-shaped workpieces. Such as shaft parts, rollers, etc.

CNC Flat Bed Lathe Machine Applications

CNC flat bed lathe has the characteristics of flat bed structure and CNC technology. They are, therefore, able to handle large symmetrical workpieces. In the following application areas, they are often used to produce components with strict dimensional and surface quality requirements.

Why Choose Us As Your Flat Bed CNC Lathe Manufacturer

Cost-effectiveness

Our company provides cost-effective products. We consider the balance of performance, durability, and price. Customers get the best return on investment.

Comprehensive After-sales Service

BORUIflat bed CNC lathe manufacturer provides comprehensive after-sales service. These include training, technical support, maintenance, and parts supply. We can ensure that customers get the most out of their CNC flat bed lathes and get the best performance.

Global Market Coverage

We have an efficient global supply chain and distribution network. We can ensure timely delivery of products and serve international markets.

FAQs About CNC Flat Bed Lathes

CNC flat bed lathes can generally process a variety of metal materials. Such as steel, aluminum, copper, alloy, stainless steel, etc.

The operator sets processing parameters and imports processing programs through the interface of the CNC system. The movement and cutting process of the lathe are controlled through CNC code.

Maintenance usually includes regular cleaning of machine tools, and lubrication systems, checking the wear of tools and tool holders, and ensuring the normal operation of the CNC system.

CNC flat bed lathes feature high precision, multi-function, and automation. It can achieve high production efficiency. Specific production efficiency also depends on factors such as the complexity of the workpiece, the processing steps, and the cutting tools used.

Yes. CNC flat bed lathes often have versatile machining capabilities. It can complete many processes on the same machine tool.