VMC 1160 CNC Vertical Machining Center Features

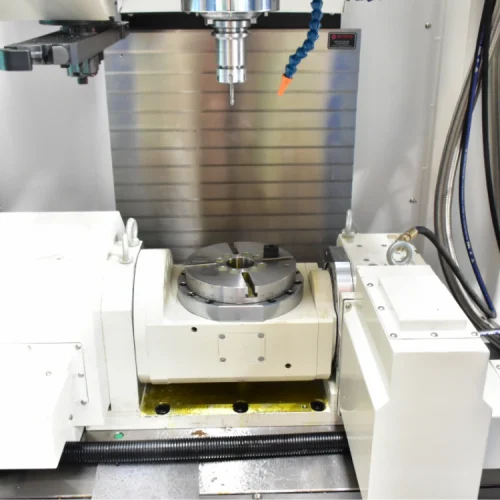

The VMC 1160 is a 5 axis CNC vertical machining center. In the standard configuration, it has three feed axes: x, y, and Z. They are controlled with three-axis linkage.

It can machine many complex parts in one clamping. These parts include discs, plates, shells, cams, and molds. It can do tasks like drilling, milling, boring, expanding, and reaming. It is equipped with a fourth-axis CNC dividing head or a rotary table. It can process more complex parts, such as spiral grooves on the rotary body.

- Resin sand casting

- 24 Disc ATC

- Taiwan VOLIS spindle

- Taiwan HIWIN linear guide

- Systems can be selected according to customer requirement

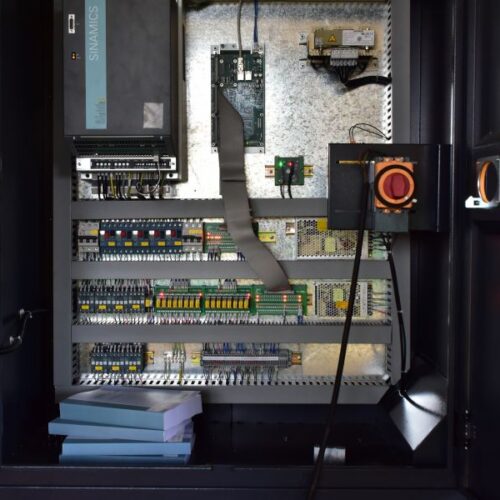

- SYSTEMCNC CONTROL

- SIEMENS, KND, FANUC, MITSUBISHl, GSK and other operating

- Full protection

- Three-axis lubricating system

- Separate hand-wheel

- Machine tool lighting work light

- Random technology document

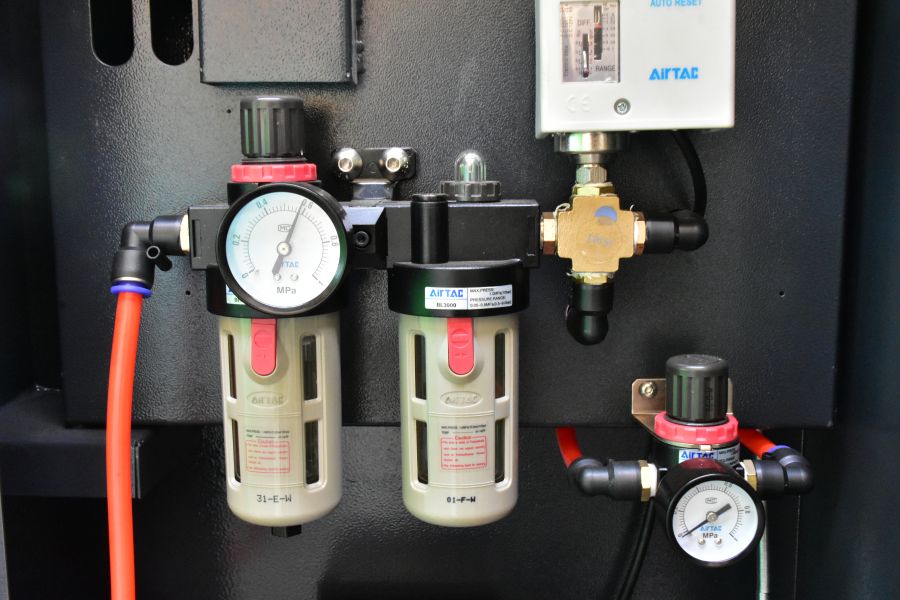

- Spindle cone Hole cleaning air

- Electric cabinet cooling and heat exchanger

- Cleaning air gun

- Chip storage tank

- Servo transformer

- Foundation pad iron and adjusting bolt

Advantages of VMC1160 5 Axis Vertical Machining Center

The bed casting of VMC1160 linear guide machining center adopts high-rigidity cast iron structure.

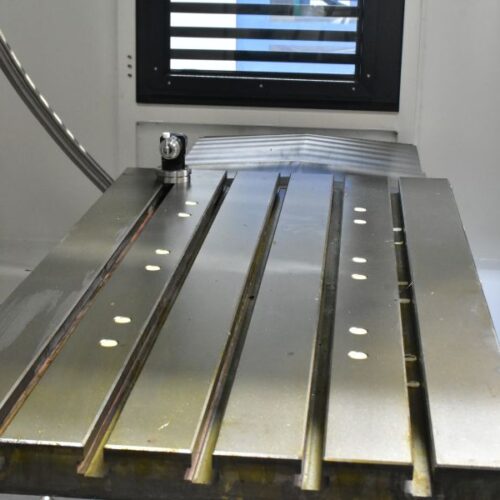

The VMC1160 linear guide machining center feeds in three directions, X, Y, and Z.

The X, Y, and Z directions of the VMC1160 linear guide machining center are all sealed and protected by stainless steel telescopic shields.

The outer protection of VMC1160 linear guide machining center is a fully enclosed structure design.

The VMC1160 linear guide machining center adopts a centralized automatic intermittent lubrication device, which is fully and reliably lubricated.

VMC1160 linear guide machining center CNC system configuration optional Fanuc system, KND, GSK, KND, Siemens system and other different grades and brands.

The 3 axis of VMC1160 linear guide machining center are detected by laser interferometer and the pitch error is compensated.

It can be professionally designed and developed according to customer requirements, and the price of the product is different for different configurations.

The Linear Guide for Vertical Machining Center

The linear guide has rolling friction. It has point or line contact. The contact surface and friction force are small.

It is mainly used in machining with small cutting amounts and fast cutting.

Features: high speed and high precision, convenient maintenance in the later period. The linear guide moves fast and can save non – processing time in mass processing.

VMC1160 5-Axis Vertical Machining Center Configuration

TAIWAN SPINDLE

Famous Taiwan Spindle

High Speed

High Precision

Good Surface Finishing

STAND COLUMN

Standard with Taiwan 16 Atc

Armless Type

24 Arm Atc Can Be Chosen As Optional

WORKBENCH

Made of High-density

High-rigidity Materials

High Strength and Good Wear Resistance

OPTICAL MACHINE

Precision Casting

Precision Machining

Precision Assembly

CNC CONTROL SYSTEM

Optional: GSK/KND/SIEMENS /FANUC /MITSUBISHI

TAIWAN LEAD SCREW

The lead screw rail adopts the Taiwan HIWIN brand, ensuring high strength and precision.

Application of Vertical Machining Center

AUTO PARTS

AUTOMOBILE HUB

DRILLING AND TAPPING

FACE MILLING TESE

IRREGULAR WORKPIECE

-500x500.png)

Reviews

There are no reviews yet.